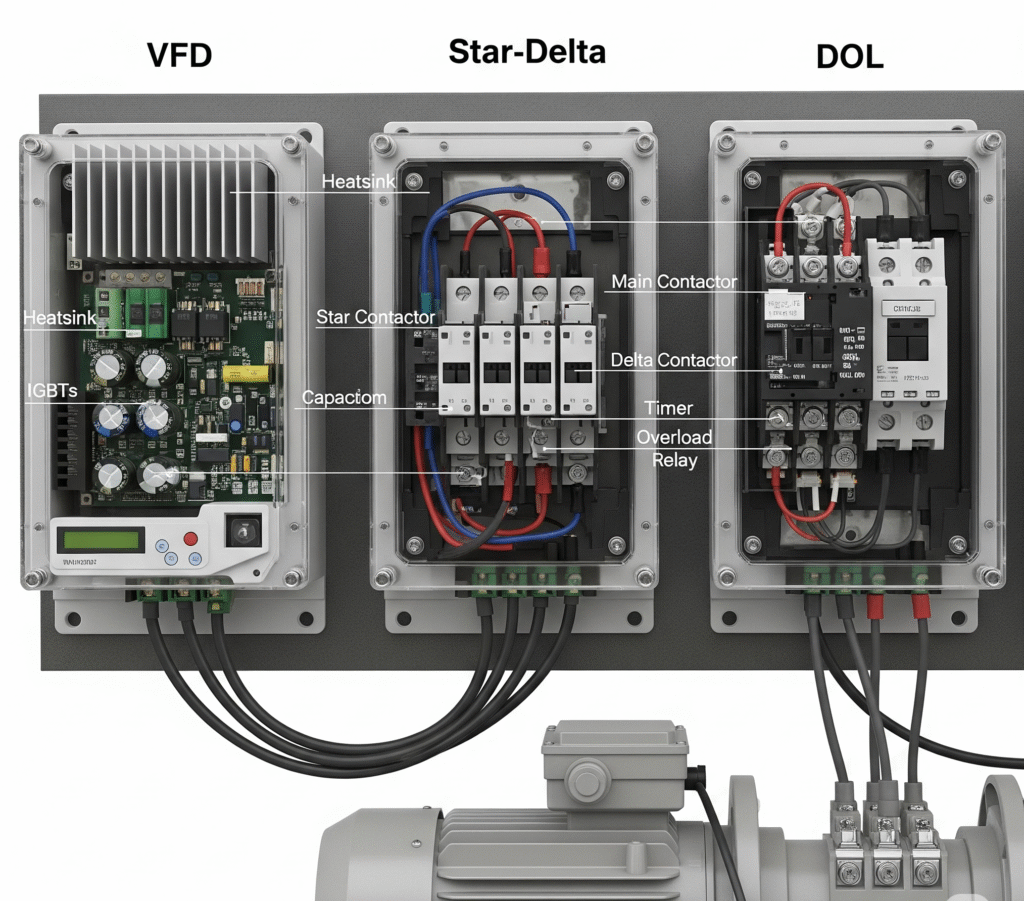

1. Direct-On-Line (DOL) Starter

The DOL starter is the simplest and most common type. It directly connects the motor to the full line voltage, starting it at full speed immediately.

When to Use It:

- Small to Medium Motors: DOL starters are best for motors with a power rating of up to 5-10 HP (or where the local utility permits a high starting current).

- Low-Inertia Loads: Ideal for applications where the motor starts without a significant load, such as small fans, water pumps, or compressors.

- Cost-Sensitive Projects: It’s the most cost-effective and simplest solution, requiring minimal components and a straightforward control circuit.

Drawbacks:

- High Inrush Current: The motor draws a very high starting current (5-8 times its full-load current), which can cause voltage drops in the electrical supply and may be prohibited by local regulations for larger motors.

- Mechanical Stress: The abrupt start puts significant mechanical stress on the motor and the driven equipment, reducing its lifespan.

2. Star-Delta Starter

A star-delta starter is a reduced-voltage starting method. It connects the motor windings in a “star” configuration during startup, which reduces the voltage and starting current. After a few seconds, once the motor reaches a certain speed (around 80% of its full speed), it automatically switches to a “delta” configuration, applying the full line voltage for normal operation.

When to Use It:

- Medium to Large Motors: This starter is a popular choice for larger motors that cannot be started with a DOL starter due to high inrush current. It is typically used for motors in the 10-50 HP range.

- No-Load or Low-Inertia Applications: It is most effective for applications that start with very little load, such as pumps, compressors, or large fans. It is not suitable for high-torque applications.

- Reduced Starting Current: It reduces the starting current to approximately one-third of the DOL current, which helps protect the electrical grid and the motor.

Drawbacks:

- Complex Wiring: It requires more contactors, a timer, and more complex wiring than a DOL starter, which increases cost and maintenance.

- Reduced Starting Torque: The reduced voltage also means a reduced starting torque (about one-third of the DOL torque), making it unsuitable for heavy-duty starting applications.

- Second Current Spike: A momentary current spike can occur during the transition from the star to delta configuration.

3. Variable Frequency Drive (VFD)

A VFD (also known as a Variable Speed Drive or VSD) is an electronic device that controls a motor’s speed and torque by varying both the frequency and voltage of the power supplied to it. This provides the highest level of control and efficiency.

When to Use It:

- Variable Speed Applications: This is the most significant advantage. A VFD is perfect for applications that require the motor speed to be adjusted, such as pumps, fans, and compressors that need to maintain a constant pressure or flow.

- High-Torque Starting: Unlike star-delta starters, a VFD can provide full starting torque at very low speeds, making it ideal for high-inertia or heavy-load applications like conveyors, cranes, and crushers.

- Maximum Energy Savings: VFDs are the most energy-efficient option. By allowing the motor to run only as fast as needed, they can achieve significant power savings, especially in “variable torque” applications like fans and pumps.

- Complete Control & Protection: VFDs offer superior control over acceleration and deceleration, and they include built-in features for motor protection (overload, over-voltage, etc.) that simplify the control panel design.

Drawbacks:

- Highest Initial Cost: VFDs are the most expensive of the three options, though the energy savings often provide a rapid return on investment.

- Harmonic Distortion: They can introduce harmonic distortion into the electrical grid, which may require additional filtering depending on the application and local regulations.

Conclusion: Which Starter Is Best?

There is no single “best” starter; the best choice depends entirely on the application’s specific needs and budget.

- Choose a DOL starter for small, low-cost projects where a direct, full-speed start is acceptable.

- Choose a star-delta starter for medium-sized, no-load applications where you need to reduce starting current without the cost of a VFD.

- Choose a VFD when you need precise speed control, maximum energy efficiency, or have a high-torque, variable-load application. While the upfront cost is higher, the long-term operational savings and enhanced control often make it the most intelligent choice.